The Bridge Between Design and Engineering

We have over 16 years of experience working with leading automotive brands turning their vision into reality: we transform bold ideas into precise surfaces that are ready for manufacturing. Working closely with designers, engineers, and tooling specialists, we provide the vital link between concept and production.

Class A surfacing represents the highest industry standard in 3D modeling—a design process focused on creating perfect, production-ready surfaces that define the look, feel, and quality of a vehicle. The method is uniqe in its consideration for both technical and aesthetic requirements of a product.

We collaborate with you to define the key details and bring your idea to its full potential: every curve and edge is crafted to reflect the design intent while meeting the most demanding engineering and manufacturing standards.

What is A Class Surfacing?

A Class surfacing originated in shipbuilding and aircraft construction, demanding absolute precision. Today, it represents the highest quality standard in 3D digital modeling for the automotive industry.

Key advantages of A Class surfacing:

- Accomodates requirements of both aesthetics and engineering:

Bridges design vision with manufacturing reality.

- Addresses the needs of all parties involved in product development:

Aligns design, engineering, and production teams.

- Delivers the highest quality standards:

Guarantees surfaces that meet the most stringent visual and technical criteria.

- Streamlines the development process:

A systematic, detail-focused approach that helps avoid costly revisions and accelerates progress.

- Anticipates and resolves potential issues early:

Supports an efficient workflow.

From Concept to Production: The A Class Surfacing Process

- Starting with the designer’s vision:

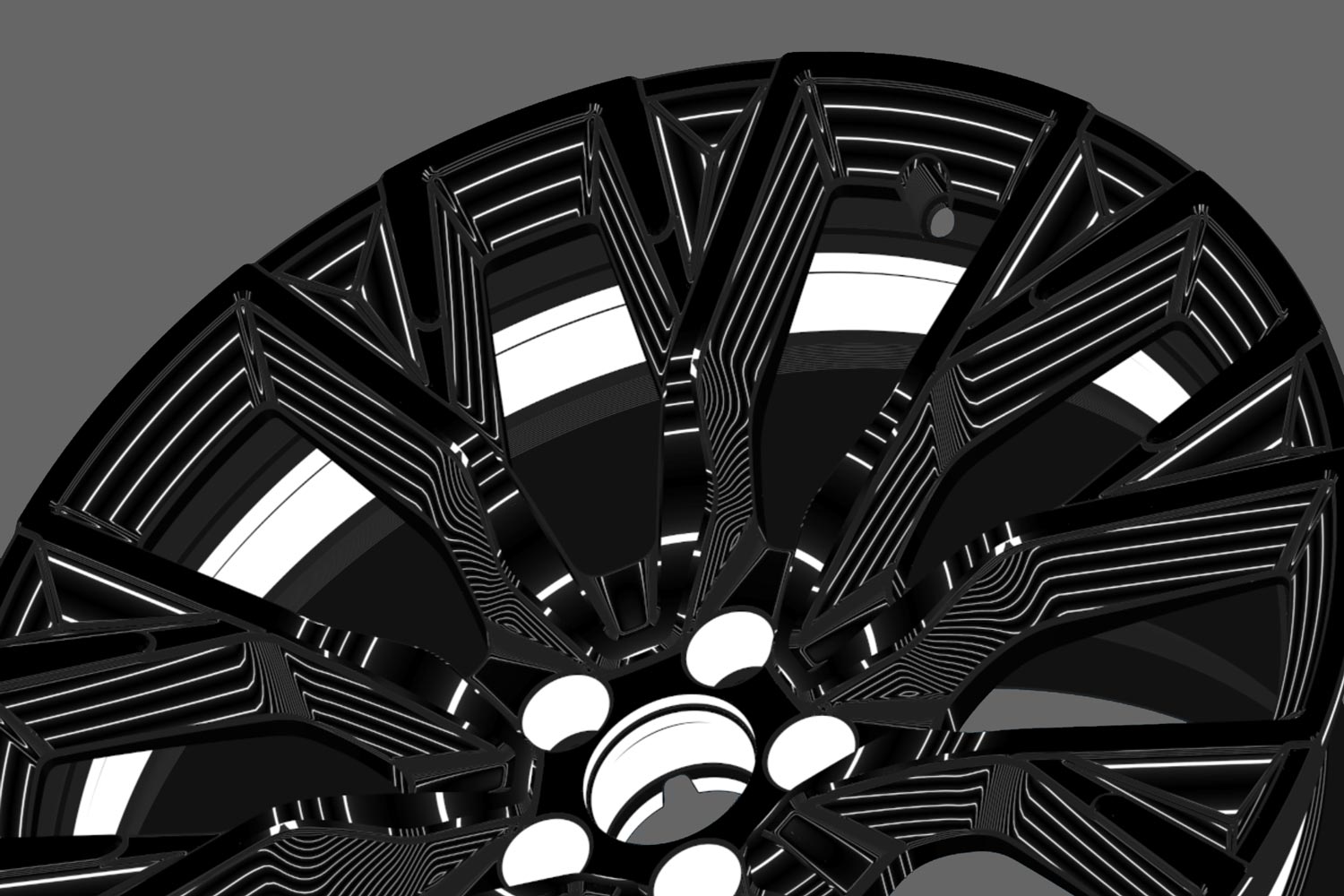

We begin with point cloud or polygon-based concept models. Our role is to refine these into a model that meets production, assembly, and ergonomic requirements without compromising design intent. - Using specialized tools:

Our team works with ICEM Surf and Alias to verify surface smoothness, curvature, and light behavior, ensuring flawless manufacturing readiness. - Iterative refinement and collaboration:

We work closely with designers at every stage, with continuous feedback between surface modelers and design team, perfecting details step by step. - Translating vision into producible surfaces:

We adjust and finalize the external form so it’s ready for production. After this stage, further changes concern internal structures, invisible to the end user. - Safeguarding quality and anticipating challenges:

Our expertise lets us spot potential manufacturing issues early, reducing costly rework and ensuring production readiness.

Highest Quality Surfaces

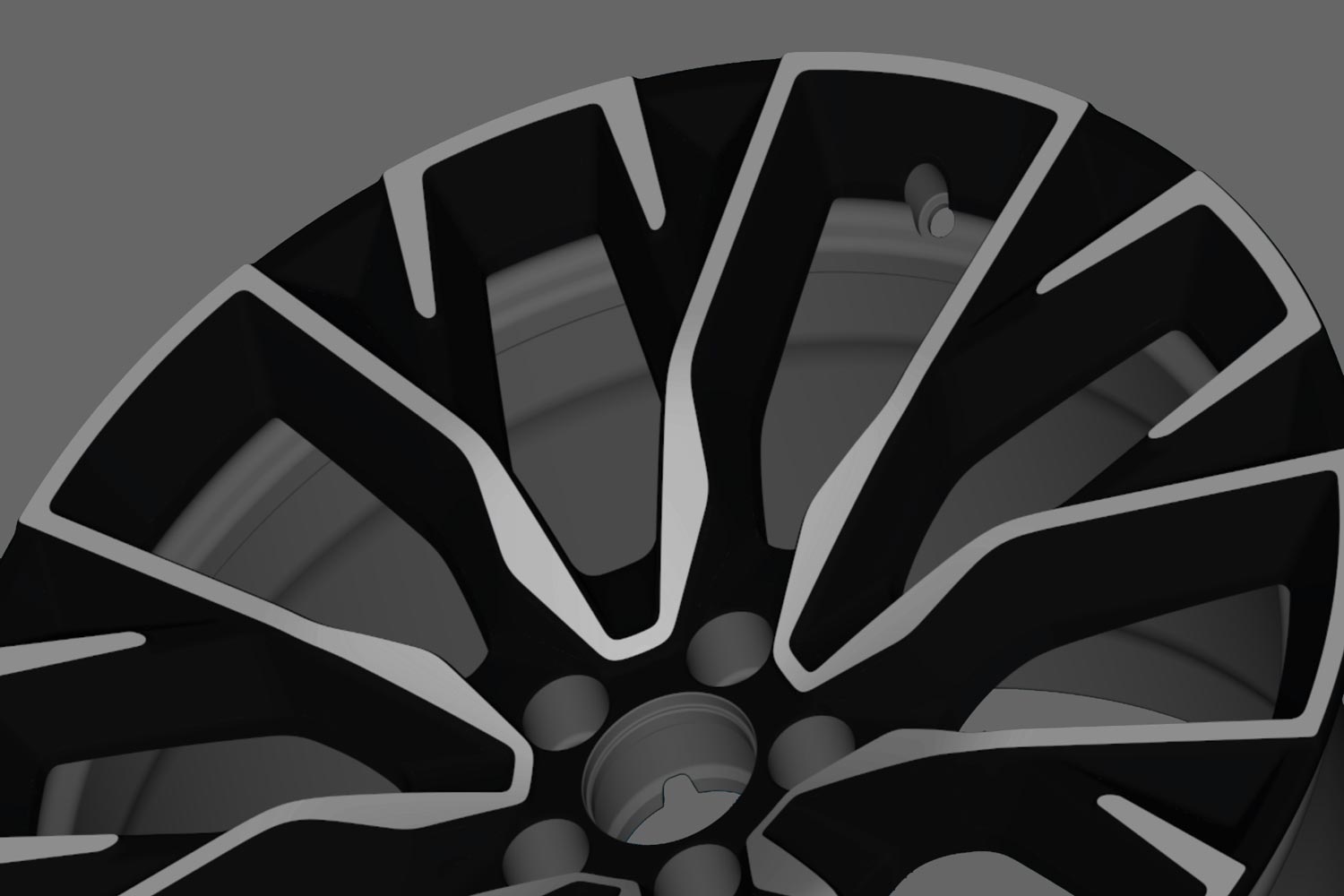

A Class surfacing ensures every surface, line, and transition is carefully shaped for a clean, uniform appearance. The precision achieved at this stage shapes the visual impact of the project, its perceived quality, and market appeal:

- Supporting efficient tooling and production:

Accurate surfaces reduce downstream issues. They enable precise tooling, minimize errors during manufacturing, and decrease the need for costly post-production adjustments—all contributing to faster, more reliable delivery. - Strengthening brand identity:

The surface finish of a vehicle plays a key role in how the brand is experienced. Perfectly refined surfaces help create a product that reflects the brand’s values and leaves a lasting impression. - Enabling bold design:

High-quality surfacing opens the door for creative freedom. With precise control over curvature and continuity, designers can explore more ambitious shapes while ensuring they meet both aesthetic and technical requirements for production.

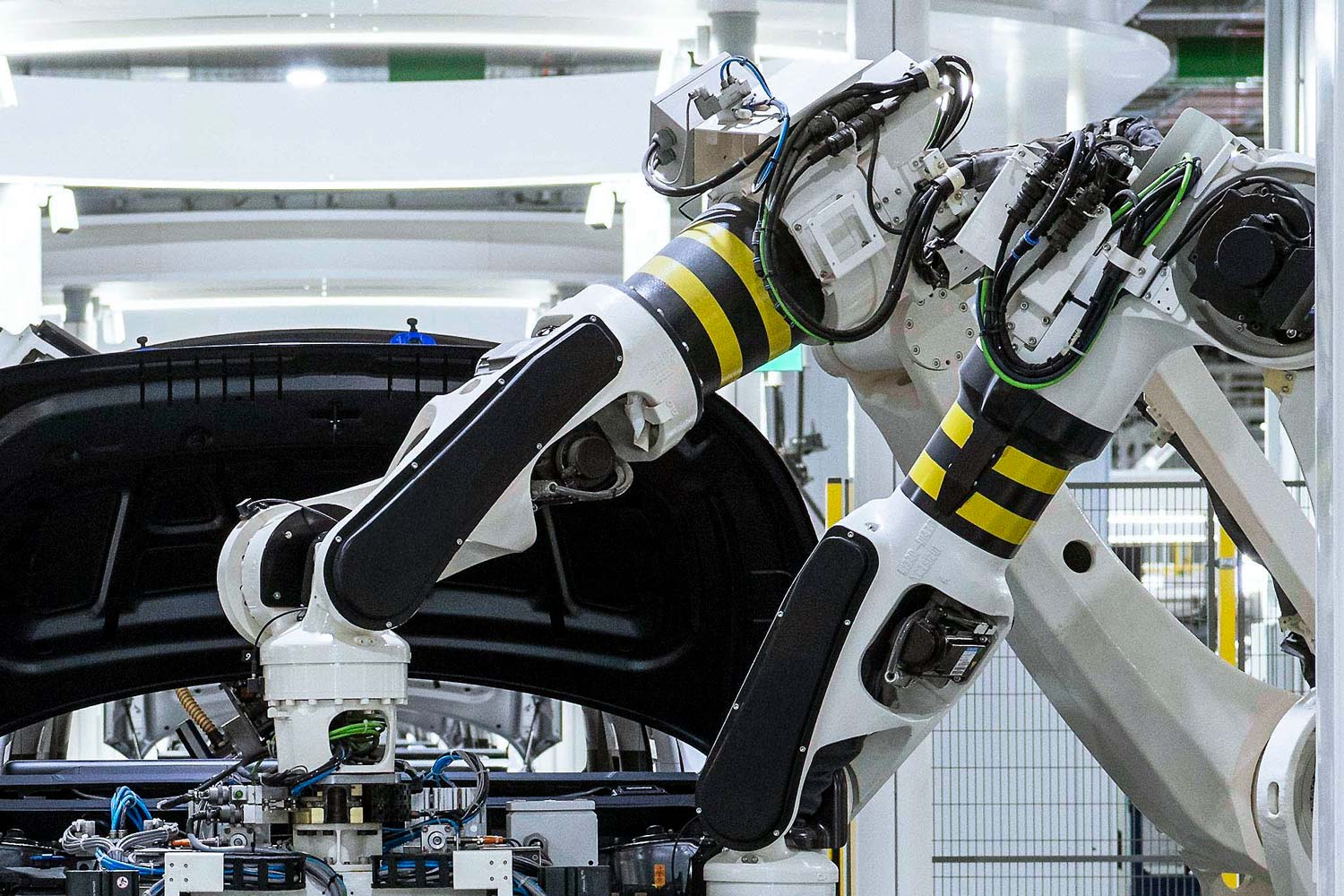

Time to Start Production

With A Class surfacing complete, your design is ready for the next stage—production. Whether it’s tooling, prototype builds, or further engineering, we help ensure that the transition from digital model to physical product is smooth and efficient.

Need support planning the next steps? Looking for reliable coordination during production handoff? Our team is here to assist you all the way to the finish line.

Start your next project with G3!

Contact us +M.Sc Aleksander Turski

M.Sc. Aleksander Turski, Senior Surface Engineer, Client Relations Manager,